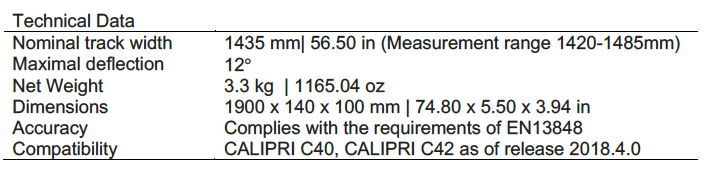

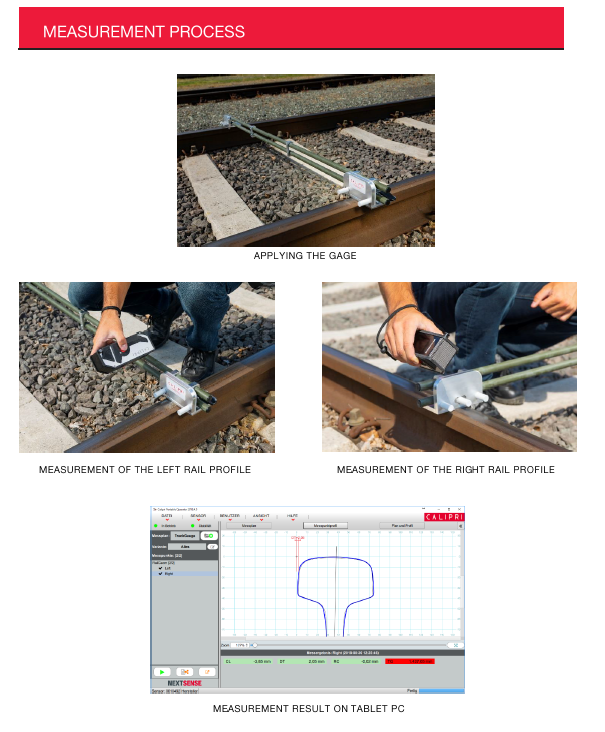

The measurement is carried out with the non-contact Calipri sensor using advanced laser light section technology and a handy GRP lightweight supporting gage. For this purpose, the gage is placed on the track and aligned at an angle of 90°. This enables the sensor to measure the rail profiles without having to turn the gage. The patented Calipri measuring principle allows not only the recording of the rail head, but also the entire rail cross section. The measured parameters are displayed on the tablet PC and on the sensor itself and can be compared with reference values. A traffic light system is used to make limit violations easily identifiable. After the measuring process, the operator can decide directly, whether measures must be taken in order to correct the track.

.png)

SOLUTION

SOLUTION

DETAILS